Productivity is the name of the game in the manufacturing space where raw materials are processed into deliverable products, which is why the implementation of AI in the manufacturing pipeline is so crucial. It can dramatically improve the efficiency of multiple production stages. Ranging from the use of deep learning to enhance the business’s predictive and designing capabilities, to the use of RPA and ML to leverage the development and distribution of the final commodity.

Look around yourself! Can you find an item that hasn’t been manufactured in a factory? Now, considering you aren’t reading our blog from a stranded island, giving an answer to this question will surely cost you a few brain cells.

Most of the items you see around in your day-to-day life have been put together on an assembly line either manually or by an automated robot, all thanks to the industrial revolution. According to a study, the use of AI in manufacturing operations is estimated to grow at a staggering 42.2% CAGR and is expected to touch margins close to $21.3 Billion by 2028. So, it shouldn’t be a surprise when I tell you that companies left and right have been implementing AI solutions to streamline their business operations.

With the proper use of AI services, a business can acquire multiple operational benefits such as reduced costs, consistent quality, zero ground-level risks, and minimal downtime in the workflow. Let’s discuss these benefits in detail across different stages of the manufacturing process in the following section!

Optimize Your Manufacturing Workflow with AI

Benefits of using AI Across Different Stages of Manufacturing

No matter what the industry is, the fundamental production flow chart remains the same- starting with a high-level idea of the product’s specifications and ending at the delivery point of the intended customers. In addition to these extremities, there are several intermediate steps that can benefit from the implementation of artificial intelligence, here’s how:

1. Better Informed Planning and Designing the Prototype

Imagine you are planning to launch a smartphone with all the latest features in the market – a high-performance processor, a cutting-edge camera lens, lightning-fast charging… basically everything that a customer will ever need. Besides, you also decide to make it super affordable Now your team starts designing the prototype but they soon hit a brick wall. They realize that designing a smartphone with your finalized features and price range while maintaining a profit margin on the selling price is only as possible as getting a dragon from Santa Clause as a Christmas present. Jokes apart, this is what a not-so-careful product planning leads to and surprisingly enough, it is still very common across businesses of every scale.

In this scenario, a custom AI platform built around your need can save you from an expensive (& frustrating!) halfway hiccup, by analyzing the market & providing your business with an in-depth analysis of the most successful smartphone models, with the associated features, pricing & USPs visualized for a quicker understanding. This way, you can effectively evaluate the crucial data and hit the right balance between user experience & profit margin, without deviating from market standards or organizational concerns..

2. Monitor the Quality and Availability of Raw Materials

An AI model won’t go to the market with a shopping bag and a list of items to fetch the raw materials for your product development, not yet at least. However, there are multiple ways in which artificial intelligence in manufacturing processes can help your business obtain the necessary raw materials more efficiently:

- Vendor Search: AI can be used to investigate multiple industry sources in order to generate leads regarding the availability of a raw material that isn’t readily available to you.

- Raw Material Analysis: Once you obtain the raw materials you were looking for, you can further take its assistance to assess the quality of the product received. However, AI can practically perform this task after every stage of development.

- Comparative Analysis: In a situation where your product is provided by multiple vendors you can use AI to analyze large amounts of vendor data to determine which vendor provides the best deal. You can further look into the pricing trends to inspect if there is a certain time of the year when the prices certainly drop.

3. Optimize Manufacturing of the Product

RPA-based solutions have been dominating the management of large-scale industries for over a decade now. This helps your business to operate in a relatively predictable manner making it relatively easier to sketch the roadmap for future business growth. It’s no secret that exploiting use cases of AI in manufacturing to the fullest can significantly improve the cycle time of individual products as well as eliminate the risk of manual errors. This is because machines can perform the same steps of a process in an identical fashion an infinite number of times.

But wait, AI-based manufacturing units are not just good at producing bulk products, you can use an AI-powered unit to step up your business's custom manufacturing processes as well! Additionally, you can train your AI model to make personalized changes on a standard based on the consumer’s instruction. This significantly boosts sales along with customer satisfaction levels as customization remains a hotspot for competitive advantage. Implementing such a solution model can help you manufacture the products under a shorter timeline, that too with a significantly better product quality compared to the manually customized products. This is possible due to the AI’s exposure to a much higher number of relevant data points and its ability to adapt instantaneously whenever provided with a new set of instructions.

4. Testing and Quality Control

Imagine you are on your way back from the office after a long day of work and you decided to stop by a general store to buy a pack of Twizzlers to enjoy on your way back home. But instead of getting the regular 9-strand pack your pack only has 4, painful right? As a business, consistency, and quality of your product are extremely important for building brand value, especially when your company is manufacturing a standardized product. With the use of AI and ML in manufacturing automation, your business can perform automated inspections either in a scheduled time frame or in case your model detects an error during production. The AI model can further evaluate the error and run a set of analytical tests to map out a report on the root cause of the error. Either you or a supervisor can go through the report to take further action on the situation.

5. Packaging and Delivery

Having a sluggish logistics setup can cripple a business’s supply chain as it impacts two major stages of the manufacturing process. Firstly, when the initial phase of deliverables is received by the production facility, which contains the raw materials required for manufacturing the product. And secondly, when the finished product is delivered either to the direct consumers of the product or the resellers who can further distribute the product in the market.

If the supply chain is not agile with the incoming raw materials and the deliverable products your business will have a hard time keeping up with the customer demands. This is because every time your supply chain fails to provide you with the required raw materials on time, it triggers a chain reaction that delays the other phases of production. If your competitors have a better supply chain they can capitalize on this opportunity and convert your clients into their own.

Now let’s discuss some of the strategies your business could apply while using AI in manufacturing to enhance the packaging, logistics & supply chain processes in multiple ways:

- RPA-Based Packaging: AI technologies like robotic process automation(RPA) can fully automate the packaging of finished products. These AI robots can handle the work equivalent to multiple humans by themselves and produce identical results every single time.

- Automated Inventory Management: AI services such as natural language processing, computer vision, and machine learning can be used collaboratively to monitor your entire warehouse and generate regular insights regarding the inventory. The manufacturing team can look into these insights to make further decisions.

- Autonomous Vehicles: These can be used for delivery without the need for a delivery agent. With technologies like deep learning, computer vision, and machine learning, your self-driving delivery vehicles can analyze the surroundings in real-time while simultaneously analyzing factors such as the optimal route to deliver the shipment at a faster speed.

- Predictive Maintenance: These delivery nodes can continuously track the status of its important parts such as transmission, engine, and others. The supervisor can track the status of each node to schedule maintenance beforehand. This mitigates the risk of infrastructure failure during working hours which can disrupt your business workflow.

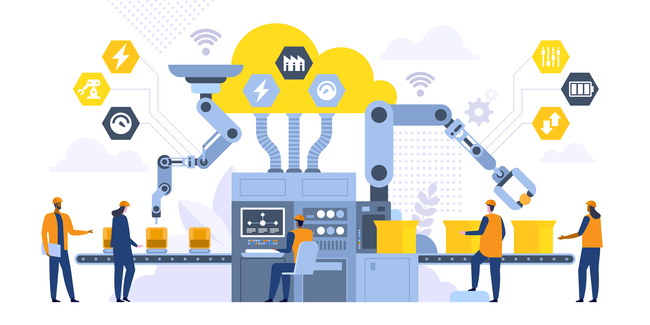

AI Use Cases in Manufacturing

The manufacturing industry observed rapid growth in AI adoption as several companies have been using artificial intelligence to optimize the entirety of their operation lines. Additionally, the use of automated robots and other simulation and analysis technologies, AI in manufacturing has been allowing businesses to streamline the supply chain and scale their operations in a way more efficient manner compared to the manual workforce.

.png)

(a) RPA to take Responsibility for the Monotonous and Heavy-Duty Tasks

A big chunk of the manufacturing process consists of repetitive tasks such as mixing ingredients or assembling different parts, or sticking labels. While humans can perform these tasks as well the robots generally take the cake from the investors as they have several plus points when it comes to this industry.

Robots don’t need breaks like humans. It is difficult for a human to work as consistently as robots without feeling tired. Robots can work continuously for months or years without ever needing rest, the only downtime a machine has is during maintenance which can last a couple of hours at max.

These days, collaborative robots are frequently spotted helping humans with a variety of warehouse operations. Unlike autonomous robots that can perform a single task, a cobot can be trained using various AI and machine learning algorithms to perform multiple in-house operations by themselves. This makes them the perfect solution for handling in-house operations that are dangerous for a human, such as heavy lifting and maintenance of machinery in hazardous work environments.

(b) A Digital Twin to Analyze and Optimize an Operation in Real Time

You can replicate your physical business to form its digital twin, this can be used for multiple operations that can help you make better workflow optimization and product development decisions without experimenting with your actual business model. Digital twins are primarily useful in two scenarios:

- Simulating Business Optimization Activities: Although the insights provided by deep learning & predictive analysis models are data-backed, entrepreneurs have second thoughts while implementing them in their actual businesses. With the use of AI in manufacturing, you can use a digital twin of your business to simulate the business recommendations provided by other analytical AI models without any hesitation.

- Monitor the Physical Model with the Twin: Let’s say, you’re manufacturing products in a highly competitive market and even a minute of downtime on your business infrastructure puts your business at a major disadvantage. So managing regular maintenance checks is close to impossible.

In this scenario, you can use sensors and IoT devices to get real-time feedback from your physical infrastructure. This allows you to keep track of the infrastructure even when it is operational and schedule maintenance only when it is necessary.

(c) Predictive Maintenance and Demand Forecasting for Minimal Operational Disruption

Maintaining the business’s machine assets is a compulsion for any business that wants a consistent and progressive business model. In case your business fails to maintain the infrastructure appropriately, the risk of operational failure greatly increases. In case a failure occurs your operational pipeline will hit a brick wall which can increase your overhead costs and shrink your profit margins. This is why implementing an AI solution model to regularly assess your business model is not a luxury for your business, it’s a necessity.

AI can also help your business to keep track of the business architecture and help your business to predict the upcoming trends in the demand for the products you supply. You can implement AI in manufacturing industries to evaluate the previous year’s datasets and identify recurring trends and predict the change in demand for every product individually. The AI model can highlight these insights to you or a designated supervisor so that the business can make changes in productivity in order to optimize business efficiency.

(d) Save Money Over Time with a Robotic Workforce

An AI model can be on the pricey end when implemented but using manual labor is way more expensive if you consider the operational costs for the years to follow. Let’s break it down. Think of it as a scale with one end representing an AI model and the other end representing a model with manual labor. Now, before we proceed further in our analogy let’s quickly compare the two side by side to give you a clear picture of their pros and cons:

- Working Hours: Compared to a standard 40-hour-per-week ceiling for a regular employee, an AI model can work non-stop for all 154 hours! Not to mention the scalability of a robotic infrastructure compared to the manual workforce.

- Ground Level Maintenance: Physical factors like temperature control, proper visibility on the working grounds, and others should be addressed in order to help the workers perform optimally. Restrooms, health and safety assessment, and human resource departments are some additional expenses that you need to account for. Compare that to the one-time investment in the AI model along with scheduled maintenance at predefined or as-per-requirement schedules.

Coming back to our scale, think of the initial money saved and the money saved over time as weights that we will put on both sides of the scale. Now you will notice that the AI will start off weak compared to the later choice. Say it costs you 5 times more to implement an AI model, so you have to put 5 units of weight on the opposite side of the AI model initially. But let’s say over the course of the coming quarter you save the amounts equivalent to 1/5th of the previously discussed 5 units. Not if we go by these numbers your AI production and manufacturing solution would cost the same as the manual labor model in less than a couple of years, and it's a consistent rain profit beyond that point.

(e) Error Detection

Think of it as the core aspect of the testing and quality control stage of a business. Your business can set up an image recognition model on the production line to detect every single unit individually. In case of an error is detected the flawed unit is pushed out of the assembly pipeline and the supervisor is notified. In case the frequency of these mistakes crosses a certain threshold, your development team might have to look into the reasons behind these mistakes and make changes accordingly.

What are the Challenges of Using AI in Manufacturing?

The use of AI in the manufacturing industry does not include any exclusive challenges per se. Although as a business owner, you have to account for the standard speed bumps that may occur in your AI development project. Such as:

- High Cost of Installing AI: There’s no denying the fact that the installation of a new AI model in your business operations can make your wallet feel lighter for a short time. But as we discussed in our manual Vs AI scale example, the long-term benefits of an AI model make it well worth the investment.

- Lack of Skill in the Market: Even though AI is one of the most trending points of discussion in the global market at this point in time, the market still lacks quality developers that can design premium solution models.

Lucky for you, BinaryFolks’ AI developers know the key ingredients that are necessary to design the perfect solution models for your business. We use cutting-edge AI technologies to ensure that your model can be just as efficient(if not more) as any other tool available in the market. - Data Quality: The quality of data stored in your legacy systems might not be reliable for training your AI model. Although this problem can be resolved with the help of techniques like transfer learning where we use a general pre-trained model and customize it according to your business.

.png)

Future of AI in Manufacturing – What Comes After Industry 4.0?

The manufacturing industry has come a long way since its first major shift from manual to automated format. We are now living in the fourth generation of the industrial revolution AKA Industry 4.0. It is mainly focused on interconnecting the business infrastructure with the help of artificial intelligence to enable collaborative operations across your business.

Although industry 4.0 is rather new to the manufacturing business, its impact continues to ripple across various industries. According to European Commission, by the time we reach industry 5.0, the AI use cases in manufacturing along with other technologies will lead industries toward a different goal. After developing a sustainable and resilient supply chain model the industries will begin to focus on their contribution to society.

What Makes BinaryFolks the Perfect Match to Leverage Your Manufacturing Operations

Our AI developers have first-hand experience in developing solutions for clients across the manufacturing market, making them the experts of the domain. With the help of modern AI technology, we help you identify your business pain points and implement appropriate AI solutions to ease off workflow interruptions.

At BinaryFolks, we use AI and ML in manufacturing models to leverage your business’s productivity with high-quality solutions that are on the superior end of the products available on the market. But that’s not it, we take it a step beyond to provide you with additional media and market research solutions. These help you to reach out to the appropriate customer base for your products and help you reduce your overall customer acquisition expenses with the help of data-backed insights.

Conclusion

We have successfully discussed our take on the use of artificial intelligence in manufacturing operations! Now it’s time for you to start implementing the insights you gained to take the first step toward your custom manufacturing AI model! You can count on our consultants to help you design your idea into a real-life, actively functioning model. But first let’s have a recap, just so you don’t miss out on anything!

[a] The stages of a manufacturing process that directly benefit from the implementation of an AI model:

- Planning and Designing of the Product

- Procurement of Raw Materials

- Manufacturing of the Product

- Testing and Quality Control

- Packaging and Delivery

[b] Multiple real-life use cases of artificial intelligence in improving the traditional production process across various manufacturing markets:

- RPA to take Responsibility for the Monotonous and Heavy-Duty Tasks

- A Digital Twin to Analyze and Optimize an Operation in Real Time

- Predictive Maintenance and Demand Forecasting for Minimal Operational Disruption

- Save Money Over Time with a Robotic Workforce

Get Complimentary AI Consultation

.png)

.png)