Let’s Start With

the numbers, “Around 53% of businesses consider ERP, along with CRM, to be priority investments”.

Well, that’s exactly why most business organizations are swearing by ERP software services – because, who doesn’t want to add efficiency to their business processes, that too, while curbing operational costs to a striking extent !

Switching from manually executing procedures using legacy tools & applications to implementing an Enterprise Resource Planning program, basically means integrating applications that automate various department-specific operations starting from product planning, manufacturing & development to sales and marketing,accounting & more, to a centralized database.

All Of Enterprise Resource Planning Under 10 seconds !

Enterprise Resource Planning software, popularly known as ERP, primarily refers to a software solution that plans and manages available resource usage across all the core business processes, starting from supply chain to manufacturing, services to accounts, HR to sales & everything in between.

ERP can be implemented in the form of software as a service (SaaS), as well as a complete suite of ERP applications which contributes to an entire ERP system that integrates the existing processes, enabling a smooth data flow among the application universe.

In short, a well-planned ERP interlinks each & every aspect of an enterprise and thus, improves performance and project management ensuring the executions don’t go off the plan, stick to the budget, and on a broader perspective, maintains an enterprise’s financial health while solving several departmental bottlenecks.

Top 5 Signs That Your Business Is Screaming For An ERP!

Every company runs on their own unique workflows and given that, it is certainly not possible to pick up a particular problem out of an ocean of them & call it ‘THE sign of ERP requirement!’

Instead, the businesses in dire need of having an ERP software in place mostly fall prey to similar issues rising from different departments, ultimately holding the business growth back.

Here’s a list of five such alarming signs!

[1] Too Many Business Processes & Too Many Softwares Taking Care Of Them?

Let’s take a moment out, to visualize how the information record-track-process cycle is going in your business? Chances are there, your accounts guy uses a standalone system to manage financials whereas the sales people make customer order entries in another, and there goes a hefty manual labour to synchronize mutual updates. Time is not the only issue here, accuracy holds up a red flag too, as “To err. Is human” and going through several system’s individual databases (or, using some low-end online tool, which leaves ample room for errors as well! ) and ensuring both the systems contain the latest updates is much like “finding a needle in a haystack”. That was just an instance and in reality, the number of systems in use within an enterprise is way more and the difficulty to make them all updated is..well, you already know, ‘difficult’ is an understatement!

[2] Do you still need to run all over the places searching for that one piece of information when a sudden need arises?

How quickly can you answer the question – “ What has been your lead-to-client conversion rate in the last 6 months? “

The time it will take you to just think where to fetch the required information from, is probably more than what it should take to come up with the answer !

Clearly, the fault is in your siloed data records and the manual processes you’re holding on to for reconciliation of the updates from discrete spreadsheets.

Your business requires its processes to speed up and for that, quick and effective access to updated information across the enterprise is the stepping stone.

For example, think of how high your renewal rates can climb up if your sales team could review customers’ purchase and transaction history in a matter of few clicks!

[3] Accounting getting more complex than calculus?

When you’re on a mission of diagnosing the requirement of ERP for your business, one of the most prominent signals will come from your accounts department. If your accounts department still runs on manual pen-and-paper based (or even confusing spreadsheets!) – then, this is it. The reason? All the manual efforts that go in, all the hours it takes, and still, the small gaps it leaves when it comes to accuracy, causing significant damage to the final figures in the bottom-line!

[4] Sales surviving on the edge of a knife?

A business’s growth is inversely proportional to the complexity of its inventory management and thus, making the resources available according to the operational need based on the priority is a necessity. However, when your business tracks inventory, customers’ details and sales information separately, it can severely wreck the sales functions causing considerable lag in gathering essential information and processing it. Say, a customer calls in to know if their product has already been shipped and your customer servicing agent puts him / her at hold till the next blue moon, trying to find the shipping status. That’s just a small example of how your company’s reliability (and reputation!) can go notches down due to lack of centralized access to the critical business data.

[5] Has The Thought Of Fixing IT Infrastructure Become Synonymous To A Nightmare?

Does applying Kirchoff’s law to a very complex circuit still sound easier than redoing the mess that your IT infrastructure has become?

Then you need to hear this – starting with a number of discrete software and tools to keep your system fuss-free is the first mistake you might have committed, the second would be to not take into account the screaming needs for integration and updates. Even though fixing your existing IT infrastructure might seem to be a great deal of bundles of green notes and a fair share of stress, isn’t it still better than watching the entire business framework burn slow? (Unless you are Rihanna and you love seeing things burn! )

What Business Problems Does ERP Solve ?

For enterprises, problems can come up anytime, amidst any process and quite reasonably, every business faces a different set of issues – but, that’s only while you’re scratching the surface. Once you dig a tad bit deeper you’ll notice, the answers those enterprises will eventually come up with against the 5 key questions will not have much difference, the simple reason being the same root cause!

[1] Controls Inventory Like It’s As Easy As Abacus

Taking control over inventories is troublesome – especially when they are quantitatively a lot or only a few. Having just the right inventory i.e. the supply meeting the demands to T is a dream for many manufacturers which in reality, remains a distant dream. As if striking the balance between the incoming & outgoing inventories wasn’t stressing enough, the lead time of incoming inventories adds up to the challenge.

Coming with an in-built inventory control module, the enterprise resource planning software offers clear visibility of the real-time inventory scene and with accurate inventory counts, the efficiency of production planning shoots up. The system logs end-to-end inventory, starting from the customers’ order receipt and flags every shortfall as and when encountered, sending instant alerts to the manufacturer.

[2] Counts Lot Like You Count Sheeps Before Sleeping

Whether it’s for the raw materials or finished products, tracing the lot plays a significant role for the inventory health. While the manual data entries hold a number of errors in them that’s enough to tag the final count as ‘faulty’, the enterprise resource planning system effectively traces specific numbers of raw materials going into production of multiple ready-to-ship products. In short, ERP takes over the overall task of lot tracking both ways.

[3] Eases Material Requirements Planning (MRP)

The Material Requirement Planning (MRP) module is another reason to give ERP implementation a thought, as it solves major challenges enterprises collide heads-on when it comes to resource management. MRP helps in optimization of manufacturing capacity usage, exploring full potential of the components, material resources, and by putting the feature of sales forecasting in action, all of these while storing historical production information.

Thus, by reducing cash outflow considerably, MRP turns out to be equally necessary to pull up profitability, as it estimates the optimum production schedule with just the right sales forecasting and handling open orders, material receipts, real-time inventory status, and master production schedule analysis.

[4] Streamlines Processes Like A Reversed Prism

As a business enters a growth phase, there comes a dire need of zeroing down on one consistent way to carry out each business process, as embracing different ways for execution is synonymous to messing the process, pushing the goal further. ERP, or to be more specific, a customized ERP, puts a befitting common solution as a backbone to your enterprise, providing a robust structure with added flexibility to scale up or down based on varying needs. The unified process methodologies eases communication throughout all the departments within the business, hence accelerating towards the core goal.

[5] Access workplace out of your office room

This is for the smart businesses who are always on the go and need to access workplace off it’s physical location – ERP implementation facilitates out and out mobility, bringing your workplace at your fingertips, so you can access even the most critical business information in just a few clicks at any given instant, without having to stop by.

ABCs Of Custom ERP

What is a Custom ERP Software?

Customized ERP is fed with solutions to your own unique business problems and elements to enhance the effectiveness and efficiency of your well-thought business processes, and implements your workflow to meet your end goal, without modifying the flow for anything except betterment, that too, only with your consent!

Cost of Custom ERP

Practically, a custom software can not have a price tag imposed upon, as it’s not just dependent on the number of screens or functionalities, but on the complexity of it & custom ERP is no exception. Complexity on the backend to be precise, to make it more intuitive on the users part.

So, there’s no point of vaguely throwing some fixed digits if it can’t be followed through.

Nevertheless, keeping every factor in mind, the range for custom ERP development can be stated as something within $50K to $2M.

Read more : Off-the-Shelf vs Custom ERP – How Much does Custom ERP Cost?

Risks In Custom ERP Development

Custom ERP certainly does wonders for an enterprise contributing to varied aspects, but going about just any Customized ERP is far from a wise decision!

Amidst an ocean of self-proclaimed custom software developers mushrooming all over the internet search results, to associate with the best in business is the real deal, but you can hit the bull’s eye on point if you keep in mind the following risk and focus on avoiding them !

.png)

[1] The Development Time Is Higher (To Make Your Business Processes Faster!)

Custom ERP concentrates on executing features entirely aligned with your mission & vision. Thus, from ‘understanding the details that you are looking for’ to ‘discussing every milestone to understand if the “done” complements what was said’, it is not anything closer to an overnight affair.

.png)

[2] Choosing The Right Enterprise Software Development Team

Think about it – can you let your daughter who makes Barbie fashion jewelry out of her playset, make your sister’s bridal neckpiece?

Clearly not !!

Similarly, putting your software requirements in the wrong hands will most obviously draw adverse results. More so, because customized ERP services require streamlined expertise in multiple tech arenas depending on the components that do best justice to your requirements resulting in a robust system maneuvering around future modifications with ease. So, make sure you don’t fall victim to fake promises and only choose the best in business to develop your custom ERP with the right experience & expertise.

.png)

[3] Don’t Skip Consistent Communication With The Development Team

The list of risks doesn’t end at choosing the right team of developers and shifts to active participation in discussing gradual progress once the development phase kicks off, simply because you understand the system better than anyone! So, from design to testing, QA to training – you should be the one on top of decisions.

The list of risks might be long, but the benefits you can reap out of a customized ERP is way longer as it helps you save a hefty amount in the long-run.

‘How?’ should be the obvious next question.

Continuous growth is on every business’s wishlist, and that implies quantitative increase in workforce. Generally, a higher headcount of users hint at skyrocketing expenses for the licensing needs in case of Off-The-Shelf (OTS) packages.

So the bottom-line is, what an OTS will charge you over it’s service period summing up the existing & new user licenses along with the post-implementation support will clearly go beyond the total development costs of custom ERP. The best part is, as you opt for customized ERP, you own the solution and retain your USP, too.

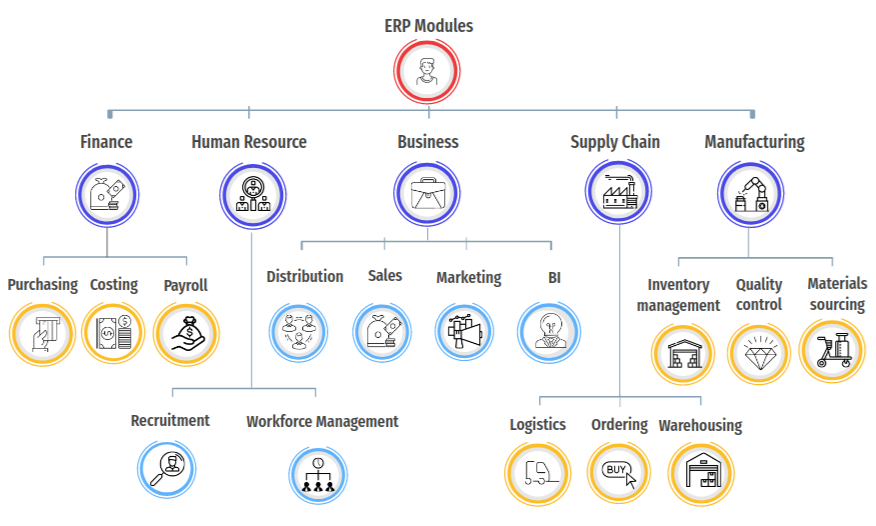

Fully Integrated & Customizable Modules For ERP Systems

The modules of an ERP

ERP broadly focuses on two major tasks –

- Unifying business data across the entire enterprise

- Automating maximum number of business processes to the highest extent

While it’s true that the various ERP modules can function with full potential individually, it’s the synergy of the modules that adds value to the business’s bottom line.

Let’s take the purchasing module and the sales modules of a customized ERP for an instance – clearly the purchasing module can get the financial department fully covered & similarly, the sales module saves the customer service agents’ time and effort to a great extent. But practically, the integration between the purchasing and sales module is what speeds up the process as well as brings the operational costs down simply by synchronizing the purchase history with the customer servicing needs !!

ERP does’t contain very few modules and that’s where prefixing the word ‘customized’ adds value – let me tell you how ! Your business processes are unique and so are its needs and so, quite justably, you might not need the entire set of modules that ERP comes with and at the same time, the combination of the same modules that is proven to be successful for another enterprise might be of least significance (if not of NO importance at all ! ) to our business. Along with the must-have modules of an enterprise resource planning system that almost every business can reap benefits from, opting for a customized ERP allows you to choose the other module that will be beneficial solely for your business.

Let’s have a look at the 6 must-have ERP modules

- Inventory Module

- Purchasing Module

- HR Module

- Accounting Module

- Business Intelligence Module

- Sales Module

The above module names are self-explanatory, as ERP simply automates the tasks your departmental employees manually performed so far, with very little to no human intervention!

But the question you might have is, what makes the above 6 stand out as the ‘Must Haves’ while I suggest picking the rest of the modules only if you need them. Let’s dig deeper here !

Why Are The Above 6 Modules ‘Must Haves’ ?

To find this answer, ask yourself the following questions first :

Plot 1 : A customer calls up asking if a particular product is available. How do you want your customer service agent to handle this query?

By checking availability under a few seconds punching the product code,

OR,

By putting the customer call on hold while he runs from system to system trying to have a look at the inventory ?

You will probably choose the former and there’s not a more effective way to ensure that, except a well integrated sales & inventory module.

Plot 2 : It’s the end of a year and the time to analyse how the business strategies which have been in place, performed. How do you want to go about it?

By churning out your gut feelings and taking a decision out of that,

OR,

By gathering insights straight out of the analytics and reports and taking the factual way, instead ?

In today’s competitive market, every decision has the potential to either make or break your business and thus, you don’t want to take chances with your brainchild, I bet! So keeping the guessing game saved till the next super bowl would be wise for now, and integrating the BI and sales module as a part of your customized ERP would be wiser!

Plot 3 : It’s time to credit the salary & there has been some new recruitment as well as a few employees left the organization very recently. What’s the best way you feel your accounts team can handle this?

By communicating with your HR team manually and logging the received information accordingly in the accounts system to credit the salary accurately,

OR,

By simply collecting information from a centralized system where it reflects new employee additions and removals including individual performance stats at the Accounts’ department just as soon as the HR team updates it!

Time is money and a smart business wants to compromise none! So, the latter becomes the obvious choice, prominently pointing at the necessity to integrate the HR module with the Accounts’.

Plot 4 : You receive an order and now you need to estimate a date for delivery. Which one seems to be more efficient?

By informing the inventory in-charge about the order placed and wait for him to get back with a date as he digs in the warehouse to find what’s where and how much would it take to fetch and deliver,

OR,

By tracking the product’s position in the warehouse and getting an estimated date from the system itself based on previously estimated time mapped against product positioning

You probably would not even feel like you read the first option once you are given the next – clearly, inventory integrated with the purchasing module is an instant YES.

.png)

Steps to Choose The Right ERP For Your Business

Legacy tools & methods require a fair share of manual efforts, hence business processes don't get competent enough and thus, the cutting-edge trends & market challenges remain unattended. Pitching right in here, the enterprise resource planning system facilitates better mobility & on-point analytics.

On that note, there are a plethora of ERP solutions selling like hotcakes but the stats record, only 67% describing their implementations as successful

What’s wrong with the other ERP systems, you ask? Well, they will still allow you to store sensitive business data & use them to support decision making – just with little to no security, lesser precision. In short, an ERP picked at random will only slightly improve your existing business processes. So, here’s all that you need to know before you start your ERP hunt! A significant reason for ERP implementation is to integrate the entire set of business operations in action, into a unified system and thus, enhancing their productivity altogether. Keeping that in mind, the enterprise resource planning software selection process should begin with a clear evaluation of all the pain points that require immediate attention. Having a list of the problem areas in front of your eyes will help you visualise the features and functionalities you want your ERP to include, easily. Don’t Just Look At The Cost – Analyze It Against The ROI Customized ERP software undoubtedly charges a few extra bucks when you keep it’s upfront pricing by what an Off-The-Shelf ERP charges, but considering the price as a strong deciding factor does zero justice unless you pay equal attention to the ROI. The right enterprise resource planning software is synonymous to business profits and thus, it wouldn’t come for peanuts. On the other hand, an Off-The-Shelf ERP software will come off as a lot more economical at the first look, but once you start using the same, customization needs will arise one after another and additional outlays would be the only way to get going with that OTS. As you sum up the expenditure following the initial purchase along with the upfront pricing that you had found lucrative, you will soon realise what makes custom ERP a more effective (& safe! ) solution ! You give ERP a thought only when you want better profit and improved growth and on that note, increase in complexities in certain parts of the business processes is as clear as day! However, make sure you don’t leave this thought behind the threshold as you plan for an ERP for your business and keep convenient provision for scaling the software in probable spaces where you might need to upsize (or, downsize) in future. Compare The Performance Of Customized ERP Against Off-The-Shelf (OTS) ERP No matter what business you have, finding a readymade enterprise resource planning software matching your requirements just right is a lot closer to impossible. However, a customized ERP system plays a pivotal role to ease the task as it enables complete optimization of the software feature set strictly to meet the exact needs of your own unique business. Read more : What To Keep In mind Before Custom Enterprise Software Development? A customized ERP is what used to be a distant dream to the businesses till the 90’s and what the biggies in the business world were soon to invest in just when it hit the market. Since then, ERP has gone through a technically strong evolution, and its popularity has been on a steep rise all through (by now, you know why ! ). Gather Your Pain Points At One Place – Know Your Business’s Functionality Needs

Think of buying a phone – would you get one that’s dirt cheap (and knocks at your door with a new upgrade even before you have earned grip over the first upgrade ), or one that has a comparatively higher pricing and serves for a decent time period with quality performance?Stick to that logic and you’ll know how important it is to look beyond the upfront pricing !

Look For Scalability

To Wrap It All Up,

Let’s do a quick tasting before your thoughts start feasting on the elaborate meal the above discussion has spread out on the nitty gritties of customized ERP – a quick look at the major reasons for how a Custom ERP overweights a OTS one in terms of performance efficiency & effectivity :