Food manufacturing software is the tech boon for today’s FMCG industry as it takes up the responsibility to ramp up the overall efficiency & productivity in significantly less time. These software ideally do end-to-end process management by automating most of the steps involved in the day-to-day operations & thicken the profitline.

Cheese, chocolates, tofu, sausages..these are common inclusions in everyone’s grocery lists but clearly, bringing them from the store to home is apparently the biggest challenge people can think of. But only the food manufacturing industry insiders know the real struggle!

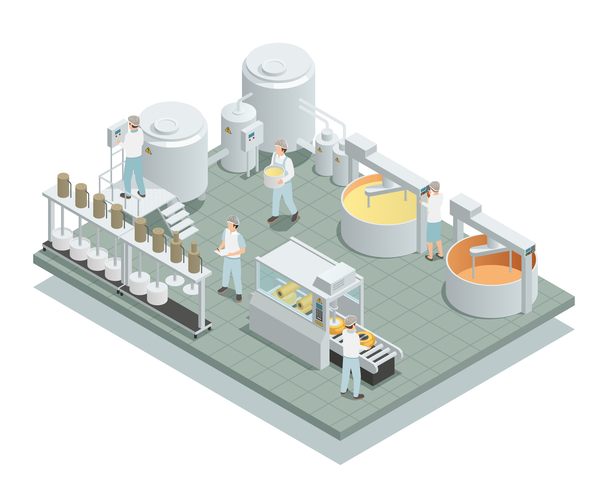

Way before shelving the products, comes the trail of steps for processing it and unlike how it’s done in the households, the entire process of bulk food manufacturing is a complex chain reaction. From purchasing raw ingredients to processing with regard to specified recipes while passing through quality compliance checks, along with more of such steps, the effort needed throughout the process is enormous. Quite understandably, relying on manual methods to get them done is equal to sealing the growth points. That’s exactly where a custom food manufacturing software steps in as a savior – introducing better speed, security, accuracy and productivity in the business operations. Let’s dig into the nitty-gritties !

Get a Complimentary Food Manufacturing Software Consultation !

What Is Food Manufacturing Software?

A food manufacturing software, often termed as a food and beverage ERP, is a digital tool to help you through the end-to-end food manufacturing process, primarily by :

- Planning ingredient purchase and usage

- Tracking inventory utilization

- Automating associated financial activities & order management

- Monitoring movement pattern of food items across supply chain

Benefits Of A Food Manufacturing Software

More than what a food manufacturing software can do, what really matters is the benefits it can bring to your business. So without further ado, let’s have a quick look at the benefits of a erp software for food manufacturing :

[1] Full Visibility Courtesy Robust Integrations

Specifically for businesses from the FnB industry, size expansion doubles a sign of growth. Be it organic or by acquisitions, they expand in due course of time and so do their needs. While the market ready software or the usual excel may suffice during the initial days of the business, as soon as the number of orders go up, those methods start to fail. So to ensure your FnB business withstands the changes while keeping pace with the day-to-day operations without a drop in efficiency, all you need is a food erp which seamlessly integrates the food manufacturing module with the associated management modules like order, finances etc.

So what do you actually achieve with those integrations? You bypass data silos through centralized information management with relevant access control imposed. Thus you get high visibility of your critical business data right at your fingertips and with actionable insights straight off the built-in analytics module, make more informed decisions.

[2] Holistic Traceability

Today’s consumers are smarter than ever, for them it’s not just the edible products’ quality but where & how their products are manufactured & delivered holds equal importance. From the ingredients used by the manufacturers to the sourcing each stands as a matter of concern and impacts brand loyalty significantly. Clearly, that also makes for a hotspot to hit if you’re in search of an aspect to build your competitive advantage around.

Food and beverage ERP eases your journey starting from raw supplies to factory to kitchen to store by automating the information acquisition for all the sequential steps. So if at any point there’s a food safety emergency, finding the root doesn’t look like a headache.

[3] Seamless Compliance Checking On Food Safety & Quality Standards

One of the biggest threats to a FnB business’ reputation is failing to live up to strict quality standards set by the food authority. Even if there’s a surge in demand, giving the compliance check a temporary pass in order to fulfill the entire demand can turn out to be an expensive mistake.

But fortunately, compliance checks can go on seamlessly even when there’s increased demand, thanks to the auto compliance checker module built within custom food ERP. By training your food manufacturing software with the complete set of applicable regulations, you can ensure smooth performance in every audit with no chance of unlabeled allergen or unethical ingredient threat.

With such traceability tools embedded in your food ERP, it's not just what goes into your product but also what all it comes in contact with, is kept noted. These granular data enable manufacturers like you to have a transparent view of the impact your processes have across the supply chain.

[4] Higher Product Acceptance

In this ever-competitive market the consumers are spoilt with choices and that causes their expectation to skyrocket. That means, contemporary customer satisfaction is directly proportional with the brand reputation and your product has to hit the right balance where the price-point isn’t abnormal yet the product has a distinguishing factor.

From auto-checks through smart sensors to AI-driven analysis for anomaly detection – your custom food and beverage software can guarantee what reaches your customers as an end product is clean. Be it the product consistency, texture, weight, look & feel or a factor alive that decides your product’s performance in the market, a dedicated ERP can keep you on top of all, identifying and discarding the red flags along the way. The benefit? Higher than ever customer retention and profitability.

[5] Automated Operation Scheduling

No matter how much attention is put, if done by manual efforts only, repetitive bulk tasks are sure to have mistakes. But as you automate your day-to-day food manufacturing operation cycle and schedule the sequential steps, you no longer have to worry about delays & errors that could affect the final outcome.

For example, equipment maintenance is a crucial part of every business from the food industry. But still, it is often not taken care of until that expensive machinery failure occurs, causing the manufacturing process to come to a standstill for a span. A custom food ERP software can take up the responsibility of monitoring the required sanitation processes and reminding of maintenance periodically (read, minimized downtime!).

[6] Efficient Inventory Management & Prediction

Having an idea of the demand before kickstarting a manufacturing process has been a dream for the FnB businesses for the longest time. Thanks to the tech advancements, food manufacturing software can make that a reality by anticipating near-accurate demands driven by historic data on demand trends. Knowing how the consumer demands have been across seasons & off-seasons saves you from two major crises that directly impact your business’ profit line – first is running out of stocks when there’s high demand & second, to have excess stock expiring on shelves itself during low demand.

Pro Tip : Integrate your stock management module with the vendor management module and check the pricing comparison right when the stock goes low. Smart refills, how cool is that?

Top 5 Signs That You Need A Custom Food Manufacturing Software

In case you are in a dilemma whether a food manufacturing software is the right investment for you at the moment – this list is for you. Mentally check the boxes relevant to you as you read along and if you end up ticking more than 2, a food ERP is your business’ immediate need !

[a] Inefficient Communication

Your employees spend a lot of time simply trying to communicate and compare supplier rates and thus more often than not you find yourself regretting the decisions made from gut instead of historic data!

[b] Clumsy Information Passing

It takes a significant time and effort of the workforce to just go back and forth across the departments to ensure that updated information is passed on but as to err. is humane..the time & efforts go in vain !

[c] Inventory Management Challenges

It seems impossible to fetch inventory details without five to six people investing their scrupulous attention leaving all other tasks for a couple of days

[d] Too Many Lot Recalls

You face frequent lot recalls to identify missing allergen declaration, ingredient alteration or such issue and lose hours of productivity in the process

[e] Difficulty With Traceability

Traceability of your food products is one of your biggest struggle as the compliances are many and passing them is a must.

Food Manufacturing Software Solutions By BinaryFolks

Based on the needs across the food manufacturing industry, we have developed the following types of solutions so far :

Food Production Management Software

Restaurant Inventory Management Software

Food PLM Software Development

Food Manufacturing ERP Systems

Quality Control in Food Processing

Food Labeling API & Nutrition Software

Food Supply Chain Management Software

FnB Quality Management Software

FnB Distribution & Delivery Management Software

Inventory Management System for Food Industry

Food Safety Management Software

Recipe Cost Management Software

Food Supplier Management Software

Food Recall Management Software

Also Read : Uber Eats Like Software Development Guide

.png)

How Much Does Building A Food Manufacturing Software Cost ?

Every food manufacturing business is unique in its own way and clearly, so are their software needs. While some make do with a simple one, others opt for a more advanced one. So to put it simply, the cost of building a food ERP depends on multiple factors like timeline & budget in mind, features & functionality of the software to be built, extent of automation, type of testing opted for, complexity of features etc.

However, to mark a ballpark range, a food manufacturing software can cost you somewhere between USD 20K to USD 80K.

Why Does Developing Food Manufacturing Software With BinaryFolks Make For A Wise Choice?

Driven by ex-engineers from Google, Amazon & Salesforce

101% Value For Money (+1 for Our Complimentary Consultation before You Spend Your 1st Dollar!)

Reviews That You Can Verify!

Safeguarded Business With An NDA

Out-Of-The-Box Innovations

Eye For Details

Questions Galore (Until Your Requirement & Our Understanding are mirror copies!)

Insight-Rich Scope Enhancement

Intense Domain Expertise

Close-knit feedback loop

Conclusion

A food manufacturing software surely can bring visible changes in your business’ bottom line within a short period of time but only if the execution is done right. In case all these information seems a bit overwhelming to handle, there’s an easy way to proceed with the process..

Schedule A Quick Meet To Discuss Food Manufacturing Software Requirements !

.png)

.png)